November 1, 2008Performance by

Design: Paul Barton and PSB Speakers

It’s been said that loudspeaker design is

as much art as science, but I’m not at all sure that’s true. Over the past year

I’ve spent many hours at Canada’s National Research Council (NRC), watching and

listening as Paul Barton developed a new series of loudspeakers. Based on that experience,

I’d argue that the proportions are nowhere near 50/50; they’re more like 98%

science and 2% art.

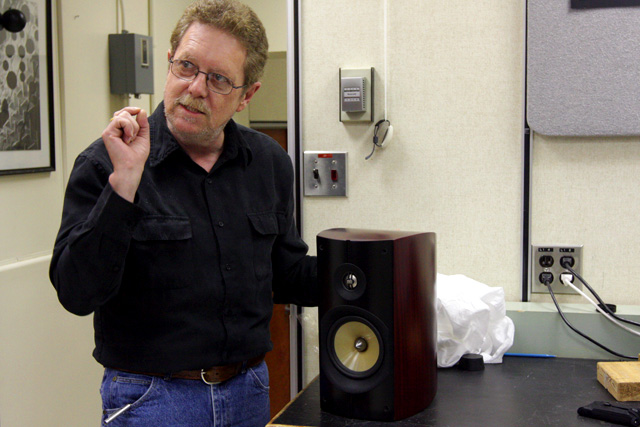

Paul Barton, founder and chief designer of PSB Speakers, is

widely respected as being one of the top speaker designers in the world today. He has been

at the forefront of speaker design since the 1970s, when he was an acolyte of the

legendary Dr. Floyd Toole, who literally wrote the book on the science of loudspeaker

design: Sound Reproduction: The Acoustics and Psychoacoustics of Loudspeakers and Rooms

(Focal Press, 2008). Toole’s work at the NRC paved the way for Canada’s

flourishing loudspeaker industry and led directly to the founding of such prominent

manufacturers as Paradigm, Axiom, and, of course, PSB. He was the first researcher to

apply to loudspeaker design the rigors of the scientific method by designing

scientifically valid blind-testing methodologies, correlating them with measured

performance, and publishing his results in peer-reviewed journals.

After leaving the NRC, Floyd Toole headed research at

Harman International; he is now retired, but the fruits of his labors live on in listening

rooms around the world. The lab he founded at the NRC is still active today, and 10 to 12

times a year it’s where you’ll find Paul Barton and his van full of prototype

speakers, drivers, and crossovers.

It’s a drive of four or five hours from PSB’s

headquarters in Pickering, in southern Ontario, to the NRC facility in Ottawa -- I asked

Barton why he continues making the trip when he could easily build his own anechoic

chamber and lab. His answer was part nostalgia and part familiarity. First, he said, he

enjoys coming back to the place where his loudspeaker journey first took flight three

decades ago. The very control room he uses today was the site of numerous design

breakthroughs, not to mention creative exchanges among the top minds of the loudspeaker

world. For Barton, the walls of this room resonate with creative energy. Nor does it hurt

that the NRC lab is chock-full of proven instruments that he can probably use with his

eyes closed. In sum, the NRC is home for Barton; when he’s working on a speaker

design, there’s no other place he wants to be.

Every speaker Paul Barton has designed in the last 30

years has gone through rigorous testing in the anechoic chamber at Canada’s National

Research Council.

|

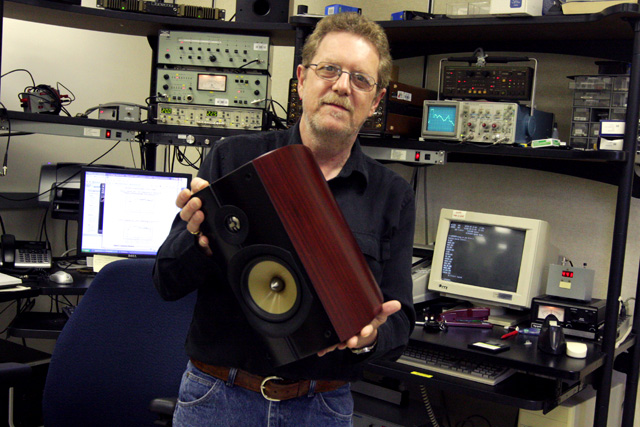

During my most recent visit to the NRC, on a

Saturday afternoon in September, Barton was double-checking samples from the first full

production run of PSB’s new Imagine loudspeaker series. I was there to pick up a pair

of Imagine B stand-mount speakers for review -- over the past year, I’ve watched the

development of the Imagine series, from rough boxes fitted with prototype drivers through

unfinished engineering samples and, finally, fully fledged retail products.

I hope that, after more than 30 years of working in my own

field, that I’ll still be as enthusiastic about it as Barton is about his. Despite

the fact that NRC lab time doesn’t come cheap, it wasn’t at all unusual for

Barton to take an hour to explain to me the fine points of selecting materials for driver

cones, or the importance of choosing the right rubber compound for a driver’s

surround. He even carries a pair of rubber balls in his travel bag to demonstrate the

importance of the surround in damping cone resonances.

As we all know from Isaac Newton, every action has an equal

and opposite reaction. The action here is the mechanical vibration induced in the driver

cone by the voice-coil. This action originates at the center of the cone and propagates

outward, toward the cone’s edge. When the vibration reaches the edge of the cone,

physics demands that it reverse direction (the reaction) and return to the center of the

cone. It’s the surround’s job to prevent that from happening: if the

out-of-phase (opposite) energy were allowed to return to the cone, it would severely

affect the driver’s output.

To illustrate that there’s more to designing a driver

surround than meets the eye, Barton showed Soundstage! Network publisher Doug

Schneider and me two rubber balls, equal in size and nearly identical in appearance. He

held one ball about two feet above a table, announced that it was made of regular rubber,

and let go. The ball hit the table and rebounded about two-thirds of the distance it had

fallen, before again descending. Over several seconds of bouncing the ball lost its

kinetic energy (as heat) and finally came to rest.

The second ball had a slightly dull sheen in comparison to

the first, but otherwise looked and felt the same. Barton dropped it onto the table from

the same height he’d dropped the first ball. However, when this second ball struck

the table, it rebounded only about an inch, and came to a complete rest on only its second

impact. "This ball," Barton told us, "is made from the surround material we

use. It has a compound added to it which is much more efficient at transforming kinetic

energy into heat. That" -- he pointed to the second ball -- "is good surround

material."

Of course, there’s more to the development of a driver

surround than what it’s made of. The trick is to develop a compound that dissipates

energy -- in other words, is "lossy" -- without making it so lossy that

the cone’s action becomes sluggish. As someone who’d thought the surround was

merely the outermost part of the cone’s suspension, I found this lesson fascinating.

Paul Barton uses two identical-looking but very

different rubber balls to illustrate his point about loudspeaker surrounds.

|

During that September visit, we were

accompanied by another talented speaker designer who had wanted to meet Barton. To hear

the two of them talk about design philosophies was fascinating, if sometimes a little hard

to follow. What impressed me was when the visiting engineer showed Barton an anechoic

measurement of one of his own designs. Noticing a peak in the midbass distortion, Barton

not only correctly diagnosed the problem, he offered a solution that, it turned out, the

other engineer had already found to be the cure -- all after looking at a single

measurement for only a few seconds. I hope that all heart surgeons are so talented at

reading instruments and graphs.

Clearly, Paul Barton works at a level far beyond trial and

error design; he knows what he wants from a speaker, and he knows how to go about getting

it. That was illustrated by the critically acclaimed and innovative Synchrony series.

Though other speaker makers may confine their best

technologies to their top-line products, Barton and PSB believe that innovations developed

for one line should, as much as possible, be shared with the others. The Imagine, for

example, benefits from work he did on PSB’s acclaimed Synchrony series, and

there’s an obvious familial resemblance. The profiles of the cabinets are similar,

and the Synchronys’ aluminum front baffles provided design inspiration for the

Imagines’ sculpted front. But while the two series may look similar in many ways,

some of the Synchrony design elements were simply too expensive to include in the

lower-priced Imagine.

PSB broke new ground with the Synchrony cabinet in using

side panels of multilayer MDF that lock into place with the front and back panels of

extruded aluminum. This technique has now been used for the Imagine series, though the

latters’ all-MDF cabinets aren’t quite as sophisticated as the Synchronys’.

To make an Imagine panel, a heavy-duty industrial press molds seven layers of MDF into

shape while simultaneously zapping them with high-energy radio frequencies. This has the

effect of microwaving the glue between the layers and transforming the entire assembly

into a single dense mass of great rigidity.

Paul Barton explains the intricacies of the Imagine

series’ cabinet construction.

|

While a glance at the shapes of an Imagine

speaker’s front, top, and bottom panels might lead one to assume that they’re

made the same way as the sides, they’re instead carved by a massive, custom-designed

sanding machine. Blocks of MDF are attached to the front, top, and bottom of each speaker,

and are then sanded down in place until the proper profile is achieved. By the time an

Imagine cabinet is ready to have its driver and binding-post holes and ports cut, there

isn’t a flat surface to be found on it. That makes it tricky to get the cabinet lined

up in the giant milling machine that makes these cuts, but engineering know-how,

tight-tolerance jigs, and lasers ensure that the cuts are made in exactly the right spots.

The Imagine’s woofer is an all-new design. Its

earth-tone color indicates that its composite cone has an inner layer of vapor-deposited

ceramic, which increases the rigidity of the cone while allowing it to remain very

lightweight. The phase plug at the center of the woofer benefits from extensive testing

done by Barton to find the perfect shape, size, and material for the Synchronys’

phase plug. The Imagines’ titanium-dome tweeter uses a voice-coil different from that

found in the Synchrony models, but its overall design was informed by work done during the

Synchrony tweeter’s development.

The Synchrony and Imagine series both have large rubber

gaskets around the perimeter of their drivers. In the Synchronys, this serves to bridge

the gap between the drivers (which are mounted on an inner baffle) and the front panel,

which is mechanically isolated from the driver mounts. The Imagines’ drivers,

however, are more conventionally mounted, in this case to a thick baffle of multilayer

MDF. The Imagines’ gasket serves a largely cosmetic function, effectively hiding the

drivers’ mounting hardware and giving the front baffle a clean look similar to that

of the Synchronys. Barton beamed when discussing the rear panel’s rubber trim, its

sculpted design flowing from the binding posts at the bottom to the driver port at the

top. "Look at how tight this fit is!" he exclaimed. "It took a lot of work

to get these shapes to come together, because the curvature of the cabinet and the rubber

piece has to be exactly right or you’ll see gaps between them." Sure enough, the

fit was as tight as that of an Apple iPod. It looked great, too.

The Imagine models are available finished in cherry or

black ash, and, like the Synchronys, the real-wood veneers are beautifully applied. Two

aspects of the Imagines’ finish of which Barton is particularly proud are the

matching of veneers between speaker pairs, and the fact that the "cathedral"

pattern in each piece of veneer (i.e., the center of the veneer sheet has an

inverted-V pattern reminiscent of a church steeple) is centered on the sides and top of

each speaker. If there’s a cathedral on each side of the speaker, that means that the

seams of two pieces of veneer must meet on the speaker’s rear panel; indeed they do,

but if you can see a seam anywhere on an Imagine, you’ve got better eyes than mine.

The quality of the veneer work is spectacular for a speaker at any price, and remarkable

considering the Imagine B’s retail price of $1000 USD per pair.

Paul Barton presents the production Imagine B, another

design developed at the lab of Canada’s National Research Council.

|

The real tests of Paul Barton’s -- or

anyone’s -- speaker designs take place on showroom floors and in consumers’

homes. But before a PSB speaker ever gets to the production phase, Barton must be

completely happy with it. He measures, measures, and measures again, each time quantifying

a design’s progress until he sees results that he knows will be pleasing to the ear.

That might not sound very romantic, but it’s the truth. Good speaker design

can’t be faked, but it can be measured -- and, as Paul Barton and PSB Speakers have

proven again and again, it can be repeated. Look for my review of the PSB Imagine B here

at GoodSound! on November 15; we’ll see how all his measurements have

translated into real-world performance.

. . . Colin Smith

|